PP PS PET PE EVA EVOH Multi-Layer barrier sheets extrusion line

Babban aikace-aikace don irin wannan zanen gado

An nuna shi tare da kyakkyawan aikin shinge, anti-oxygen da anti-danshi yi, ana amfani da zanen gado don shirya Jelly, shirya yogurt, shirya nama, shirya kayan ciye-ciye, shirya abinci mai inganci, shirya shinkafa da sauri da kuma shirya magunguna. , shirya kayan kwalliya da dai sauransu.

Amfanin wannan layin

1) Gravimetric tsarin dosing don albarkatun kasa yana samuwa, wanda zai iya gane daidai gwargwado na nau'ikan kayan aikin da yawa.

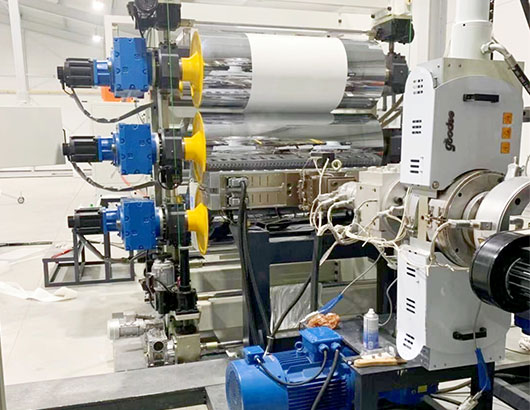

2) Advanced dunƙule da ganga tsarin zane iya gane da albarkatun kasa mai kyau plasticization da barga matsa lamba da kuma abin dogara extrusion.

3) Mai canza allo na hydraulic zai iya toshe ƙazanta daga albarkatun ƙasa yadda ya kamata.

4) Ana shigo da famfo mai narke mai narke don tabbatar da matsa lamba mai ƙarfi.

5) T mutu da na'urar daukar hotan takardu na kan layi an sanye su tare don tabbatar da kauri mai kauri.

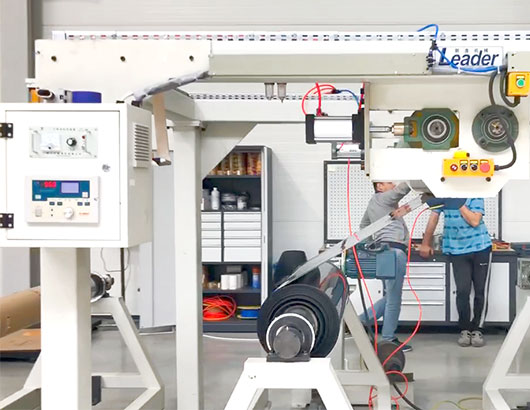

6) Kalandar nadi uku na iya ɗaukar nau'in kwance, nau'in oblique, nau'in madaidaiciya ko wasu nau'ikan nau'ikan nau'ikan ƙirar don saduwa da nau'ikan zanen gadon extrusion daban-daban.Tsarin tuki na kalandar abin nadi na iya zama na gama-gari rage ikon sarrafa motoci ko sarrafa injinan servo.

7) The online gefen datsa granulator da bututu isar da tsarin iya isar da gefen gefuna zuwa gaban extruder ta atomatik.

8) Silicone mai shafi naúrar iya tabbatar da zanen gado ana sauƙin cire daga thermoformed molds.

9) Zane-zane na tara ƙira don saurin layi mafi girma

10) Shahararrun sassan taro na duniya, kamar SHINI, MOTAN, JC TIMES, NORDSON EDI, SCANTECH, NORD, MAAG, GEFRON, NSK, ABB, SIEMENS da dai sauransu.

7)Ingantacciyar fasahar ceton makamashi tare da ƙarancin amfani da makamashi.

Dukan layin yana ɗaukar cikakken atomatik Siemens PLC sarrafa allon taɓawa;lantarki

Babban bayanan fasaha

| Mmodel extruder | LSJ-105 | Saukewa: LSJ-120 | Saukewa: LSJ-150 |

| Co-extruder model | LSJ-30, LSJ-45, LSJ-65 | ||

| Sabu mai amfani | Farashin PPPET | Farashin PPPET | Farashin PPPET |

| Pfadi nisa | 600-800 mm | 800-1000 mm | 1000-1200 mm |

| Kauri samfurin | 0.15-2 mm | 0.15-2 mm | 0.15-2 mm |

| Tsarin samfur | Mono Layer, Multi-Layer co-extrusion, | ||

| Miya aiki ax | 200-300kg/h | 400-550kg/h | 600-1000kg/h |